Home > News

> News Information

Home > News

> News Information

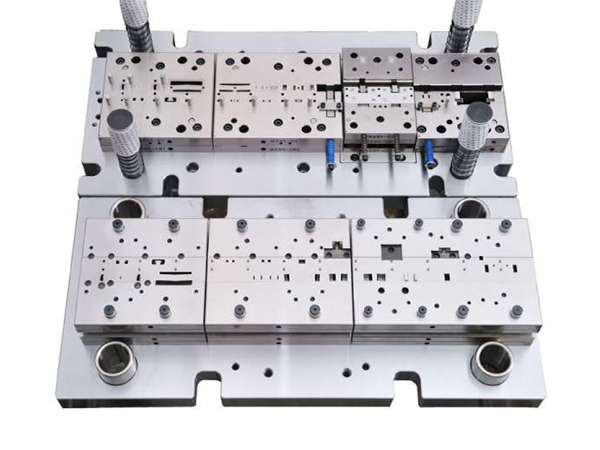

Preparation before testing the new mold for high-precision metal stamping parts: receiving the trial material, adjusting the various adjustment sliders of the mold to the outer position to avoid damaging the mold, and selecting the testing machine: considering parameters such as tonnage, accuracy, stroke, working face size, cutting hole size, mold height, and adjustment difficulty.

Precision metal stamping parts mold trial mold, frame mold: Ensure that there are no debris or other foreign objects on the surface of the punch worktable and mold seat; The mold should be at the center of the workbench and parallel to it; The mold should be securely fastened to the worktable and upper slide of the punch press; At the same time, adjust the closing height gap to 0-0.05mm. Feeding: The first feeding is done manually. Firstly, pass the material strip through the mold once (except for the guide plate type), position the material strip on the side of the feeding machine with a roller, then take out the material strip, and send it to the punching process hole station and the first positioning needle (but do not force the cutting edge on one side) for one punch. Then, accurately position it by aligning with the positioning hole and feed it one by one. Carefully observe any abnormal situations during the feeding process, such as feeding, blocking, and insufficient flashing position. Adjustment and maintenance of molds: Firstly, remove obstacles that affect the continuous feeding of stamping molds, such as material carrying, jamming, and blocking. Secondly, address the issues that affect the appearance of the product, such as chip jumping, indentation, mold marks, fraying, and insufficient flashing positions, while also dealing with material blocking issues; Finally, adjust and correct the size parameters, functional parameters and assembly parameters of the product. According to the adjustment and maintenance situation during the trial mold, truthfully fill in the trial mold report and revise the mold drawing.

Sample production and measurement, sample production: Manual or automatic feeding can produce the quantity required for size, appearance, function, and assembly performance. Sample measurement: Measure the sample size and functional parameters according to the product blueprint, and fill in independent inspection records.

Finally, submit independent inspection records of the samples, assembly test reports, and revised mold drawings to the design project.

.jpg)