1. Anyone who has used a meat grinder knows that the higher the hardness, the higher the sharpness. The sharpness of the meat grinder disc also depends on the degree and softness of the blade. The sharper the blade, the easier it is to grind meat. There are many types of meat grinders on the current market, so when choosing, it is important to check whether they are sharp, straight, and have no gaps.

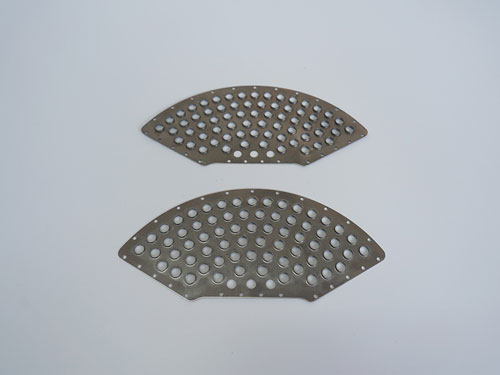

2. From the perspective of processing technology, the general production process for meat cutter discs is stamping forming. In short, it is to directly punch a complete meat cutter disc from a large steel plate through a punching machine, and then perform processes such as cutting edge, surface treatment, and heat treatment to produce the finished product. The advantages of this are high efficiency, high cost, high degree of mechanization, good surface treatment, high standardization, and more attention to details.

3. Look at the blade of the meat slicer. In terms of sharpness, steel has a higher hardness, a smaller degree of cutting edge, and a softer curvature of the cutting edge. A good meat grinder should have a straight blade and no gaps.

4. The thinness of the meat grinder disc is also important. The thinner the knife, the sharper the blade.

.jpg)