Home > News

> News Information

Home > News

> News Information

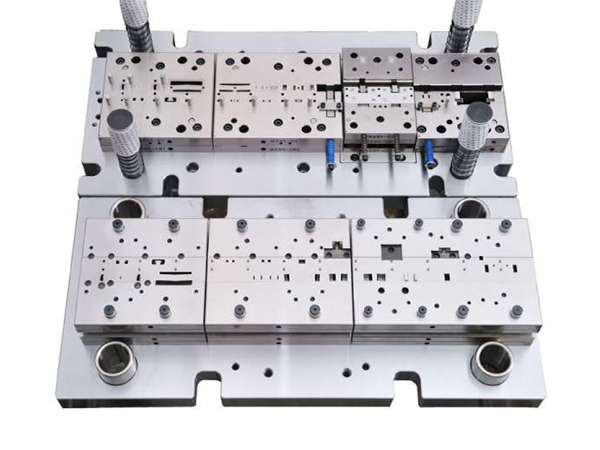

The function of metal stamping parts is to apply external force to plates, strips, pipes, and profiles through a press and mold, and to undergo plastic deformation or separation to obtain the desired shape and size of the workpiece. Metal stamping parts are widely used in daily life. Let's take a look at the characteristics and application fields of metal stamping parts.

1、 Characteristics of metal stamping parts

Compared with castings and forgings, precision stamping parts have the characteristics of thin, uniform, light, and strong. Stamping can produce workpieces with reinforcing ribs, ribs, undulations or flanges that are difficult to manufacture by other methods. Punching can improve their rigidity. Due to the precision of the mold, the precision of the workpiece can reach micrometer level, with high repeatability and consistent specifications. It can punch out holes, protrusions, etc. The surface and internal properties of stamped sheet metal have a significant impact on the quality of stamped products. Metal stamping processing has the following requirements for stamping materials:

1. Accurate and uniform thickness stamping materials;

2. Smooth surface, no spots, no scars, no scratches, no surface cracks, etc;

3. Uniform yield strength without clear directionality;

4. Has high uniform elongation rate;

5. Low yield to strength ratio and work hardening properties.

2、 Application fields of metal stamping parts

The application of metal stamping parts covers every corner of modern life, and can be roughly divided into:

1. Daily household hardware stamping parts: pots, pans, sinks, kettles and other daily necessities, as well as household appliances such as washing machines, air conditioners, refrigerators, rice cookers, etc;

2. Industrial metal stamping parts: equipment chassis shell, vehicle sheet metal, engineering machinery stamping parts;

3. Stamping hardware components for tight components: instruments and equipment, connectors, etc;

4. Special stamping hardware for aerospace, shipbuilding, and naval vessels;

5. Stamping in the automotive industry. Mainly deep drawing. Stamping for automotive components and other industries mainly involves stamping and shearing forming.

Stamping parts are widely used in hardware processing, which refers to the process of forming steel/non-ferrous metal sheets into specified shapes at room temperature using molds provided by a press machine under the required pressure.

.jpg)