Home > News

> News Information

Home > News

> News Information

With the continuous increase in the types and quantities of precision metal stamping parts, product development management has become increasingly important. How to streamline various stages of product development, reduce errors, and enhance product added value. The following points are for everyone's reference.

Firstly, the blueprint design should be precise, refined, and accurate

Some of our drawings are provided by customers, while others are designed by ourselves. After the design is completed, we need to print a complete set of drawings, carefully inspect them, assemble them using 3D design software, and check the dimensions of each stamped part.

2、 The preparation of the schedule should be completely consistent with the actual situation

The preparation of a detailed list is a meticulous task, and each part must be carefully checked and compared with the samples and drawings on site, without errors, omissions, or numerous situations.

Third, mold acceptance should not be sloppy

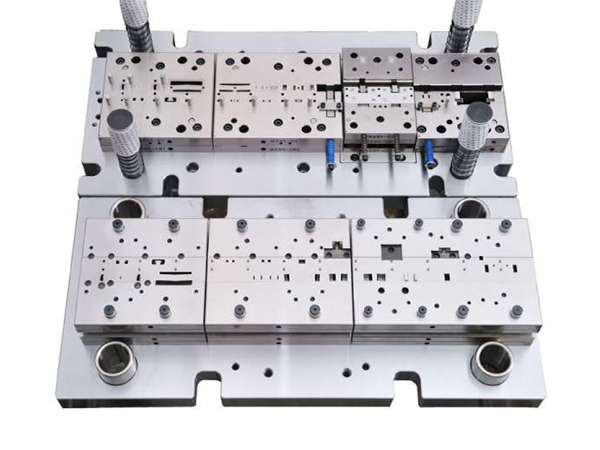

Mold acceptance is a strong task that product developers, mold designers, and mold manufacturers should all participate in. Mold material, stamping part size, rationality of mold structure, and mold life are all very important indicators.

Fourthly, product trial assembly and sample production should be able to identify issues

The purpose of product trial assembly is to discover problems, record them, and solve them one by one.

Fifth, the product hanging code should be carefully checked

Product code hanging is the most prone to errors, and we have learned many lessons in this regard. The name, quantity, material, and technical requirements of stamped parts are all very important data. If a certain data is incorrect, it will cause significant economic losses to the stamping factory. Especially for borrowing parts, product code hangers, developers, and technicians must carefully inspect them.

6、 Small batch trial production should be considered comprehensively

Small batch trial production is a link that connects the past and the future. All aspects need to be considered. After the trial production is completed, the product should be well tested and evaluated.

7、 Mass production ensures foolproof safety

The mass production of stamped parts is the most important link in product realization. Before production, all departments should communicate with each other and make all necessary preparations. All aspects should be carefully considered to ensure the smooth implementation of the product. The development of hardware products is not only the responsibility of the technical department, but also requires coordination and careful organization among various departments and workshops to create a complete and effective hardware stamping product industry chain team.

.jpg)