Home > News

> News Information

Home > News

> News Information

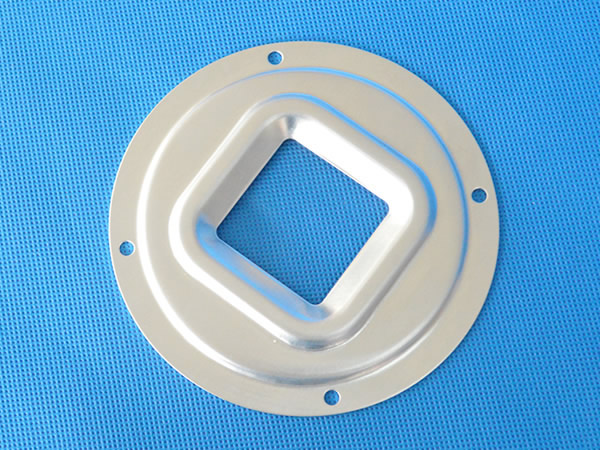

When producing precision metal stamping, if imported stainless steel material is used as the raw material for steel, the precision metal parts punched out from it often have appearance defects such as spot damage, extrusion damage, scratches, etc. When this situation occurs simultaneously, a vacuum cleaner and an exhalation nozzle are added to the punch press, but the effect is not ideal.

In fact, there are many ways to deal with this situation:

1. Cover the protective film and stick it on the material. Just ask the supplier when buying the material. During the processing, no oil or water will be added to the product. It is best to let the products come out one by one during the production process. Overlapping cutting edges can easily cause compression and collision! High cost, can be considered.

2. If it really doesn't work, you can try replacing different raw materials. Sometimes imported SUS has significantly different performance from domestically produced ones. The performance of different domestic suppliers varies, but while ensuring sufficient performance, cost control is also a way to solve the problem!

3. Adding an appropriate amount of punching and cutting oil (lubricating the punch and cutting mouth to prevent waste), regularly cleaning the mold, timely sharpening the punch, keeping it sharp, and reducing the generation of waste are also effective methods!

4. The smoothness of the mold must be good. During processing, the mold surface should be cleaned with a brush, and the mold surface and workbench should be regularly cleaned. There should be no granular impurities such as iron filings that may cause pressure damage to the material or mold surface, but the production efficiency will be reduced. Compared to the scrap rate, it is still acceptable!

.jpg)