Home > News

> News Information

Home > News

> News Information

Reasons and solutions for defects in precision metal stamping processing and metal spring bending parts 1、 The curved end face bulges, and the outer surface of the curved rounded corner strip t……

Four principles for selecting materials for precision metal stamping parts: 1. For fixed length boards, try to choose the appropriate size. After cutting from the steel plant, there is no need ……

Hardware stretching partsWhy do we need to stretch multiple times? I think it's actually useless and unnecessary. I think it's very necessary. Usually, hardware stretching parts are stretched ……

When producing precision metal stamping, if imported stainless steel material is used as the raw material for steel, the precision metal parts punched out from it often have appearance defects such as……

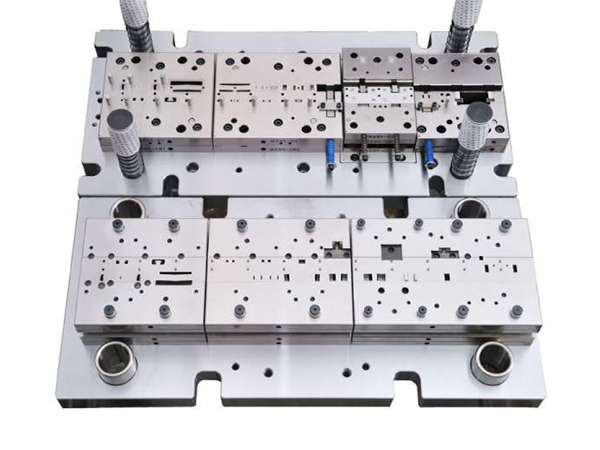

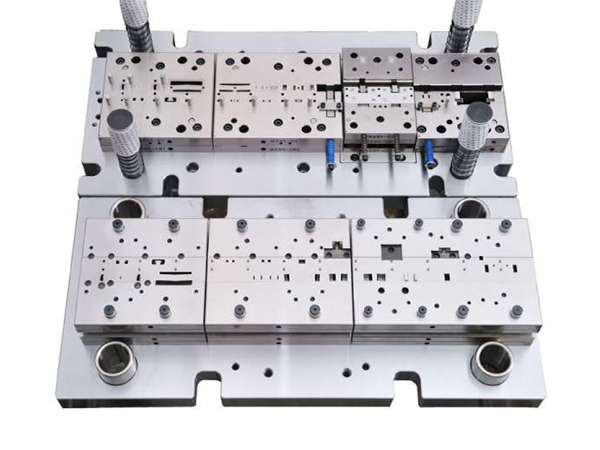

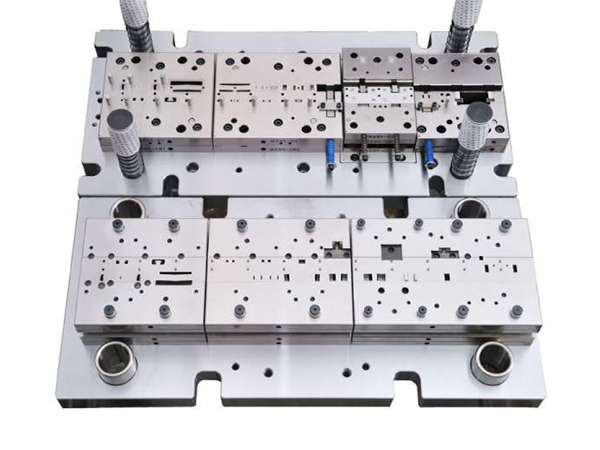

The proportion of metal stretching molds in the entire stamping mold industry is large, and there are too many factors to consider in the design of stretching molds, such as the drawing coefficient, w……

Precision metal stamping is a metal processing technology that uses stamping technology for processing. Precision means high processing accuracy, and some small stamping parts can also be processed ve……

.jpg)

What is precision metal stamping? Precision metal stamping is a large-scale metal processing technology that uses stamping tools to press materials into the desired shape and imprint them to manufa……

The knowledge of maintenance and upkeep of metal stamping molds mainly includes the following: 1. After long-term use, the cutting edge of the mold must be polished, and the surface of the polished……

Precision metal stampingIt is widely used in various corners of daily life such as home furnishings, industrial production, and automobile production. Due to its wide range of applications, covering m……

1、 Reasons for low power in precision metal stamping factories: (1) Unreasonable production sched……

Problems in the processing of precision metal stamping parts: 1. The gap between the convex and concave molds is too small, which can cause thinning and wear. During the stamping process, it is ess……

(1) High production efficiency. The number of parts or process content completed per unit time is se……